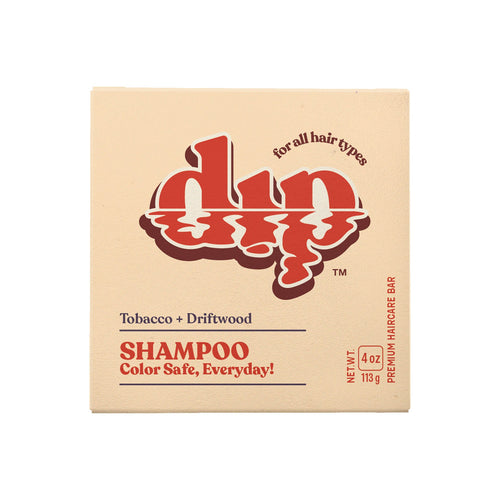

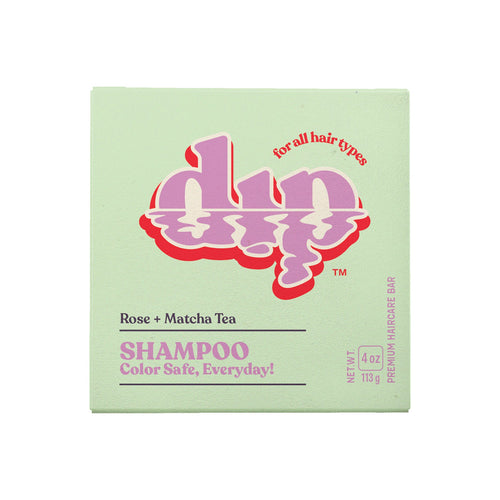

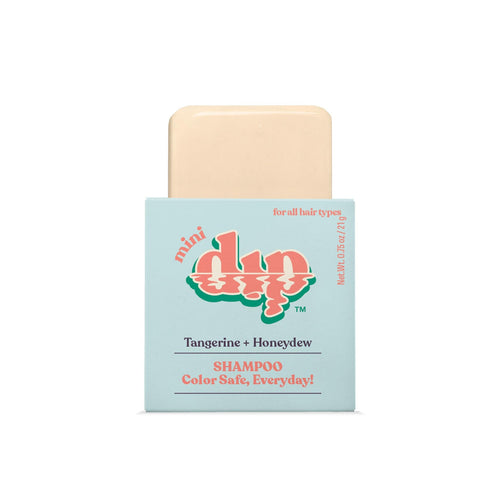

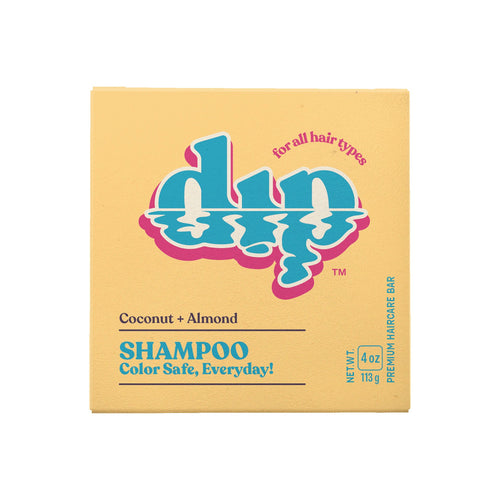

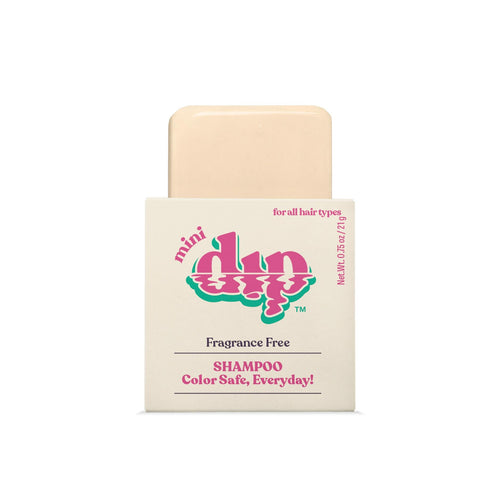

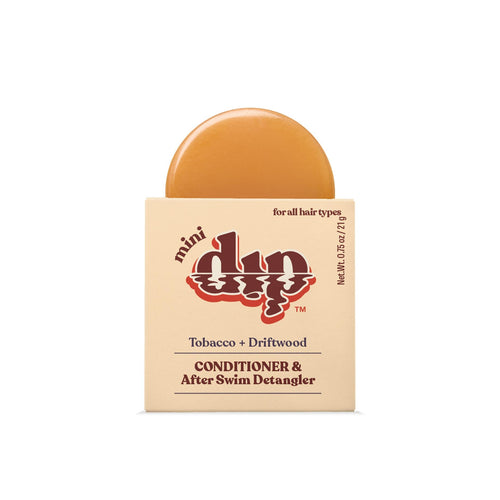

Packaging

All solid shampoo and conditioner bars come in plastic-free, recyclable, and compostable packaging. Each bar is wrapped in paper and placed in a recyclable paper box. For liquid or oil products, Dip takes a unique approach by upcycling “deadstock” plastic bottles (unused bottles from other brands) instead of sourcing new containers.

Dip ships directly from its U.S. manufacturer to customers to avoid extra transit and packaging, and it avoids using plastic pallet wrap by working with small retailers.

Ingredient Sustainability

Many formulations are built on coconut-derived cleansers (e.g. sodium cocoyl isethionate, sodium lauroyl methyl isethionate) plus plant oils and butters (almond oil, coconut oil, shea butter) and plant extracts. All these ingredients are biodegradable or naturally derived, and no persistent silicones or microplastics are used. In fact, Dip is silicone-free and uses olive-derived squalane for slip and shine instead.

Dip even considered the sustainability of fragrance components: rather than defaulting to natural essential oils (which can drive intensive farming and habitat loss), Dip often opts for synthetic fragrance compounds that are produced in controlled settings without pesticides and with fewer land impacts. These fragrances are formulated to meet Credo's clean standard (free of phthalates and other toxins).

Many key ingredients are renewable (plant oils, plant-based surfactants), and any palm-derived materials are from RSPO-certified sustainable sources.

Energy Use and Footprint

Dip manufactures locally in the USA, avoiding the long-distance shipping emissions associated with overseas production. The company's distribution model is streamlined: products are shipped directly from the manufacturer to the customer, bypassing additional warehousing or handling steps. Dip also actively encourages customers to buy from nearby small retailers when possible, rather than always shipping individual orders. Additionally, the waterless format of Dip's bars means lighter, more compact products that require less energy to transport.

Dip does not yet disclose detailed data on manufacturing energy use or emissions.

Waste Management

A standout practice is that imperfect bar products are never discarded. If a shampoo or conditioner bar comes out misshapen or dented, Dip simply melts it down and reforms it rather than throwing it away. Dip also runs a very lean inventory and avoids overproduction. The team closely monitors demand and produces accordingly, preventing excess stock that would later need to be dumped or sold at deep discount. Water conservation is inherent in their solid formulas, and there are no microbeads or microplastics in any product that would contaminate water systems.

Business Model

Dip makes products that are long-lasting and multi-functional. Each full-size bar is substantial (4 oz) and replaces many bottles of traditional product. Dip's product launch pattern and inventory management avoid the trap of constant new releases. Furthermore, Dip actively educates consumers about sustainability and responsible choices. The overall business approach is centered around quality over quantity and mindful consumption.